Half Cooked Chapathi Making Unit – Scanan Engineering: Revolutionizing Commercial Chapathi Production

Introduction

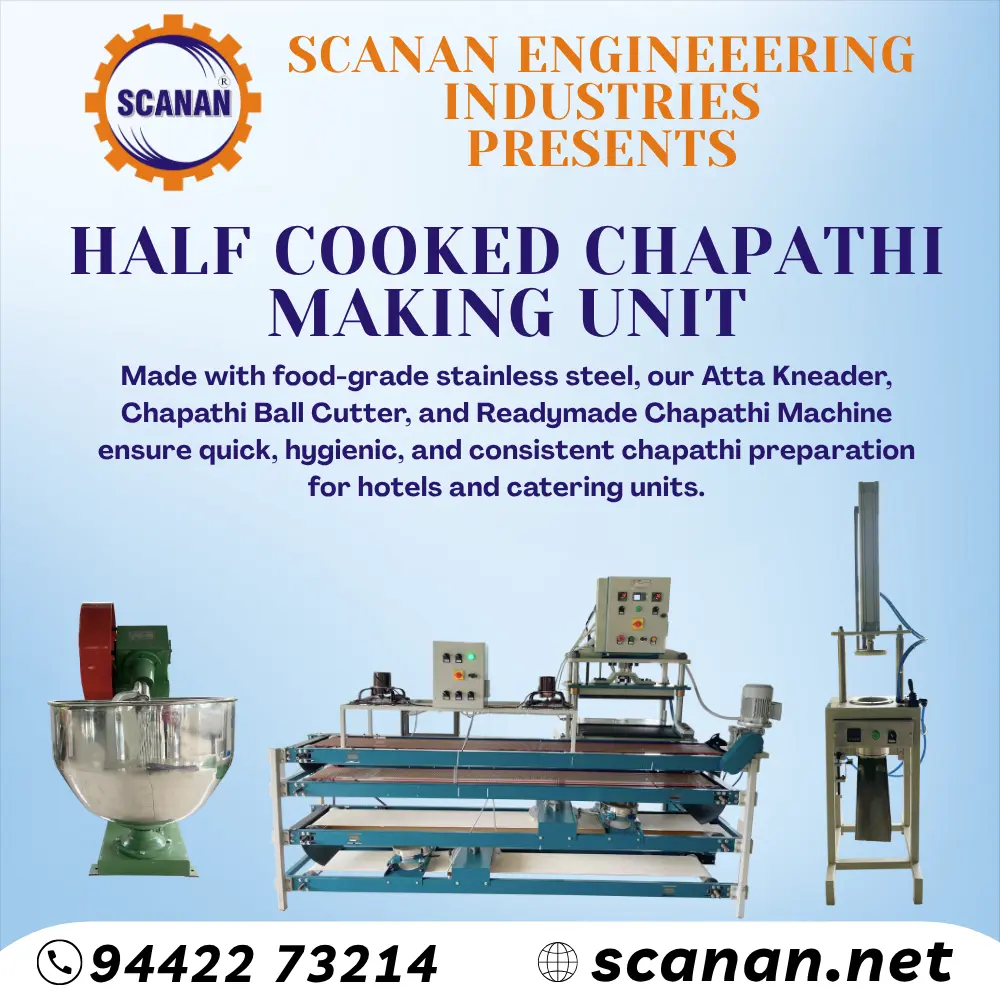

In today’s fast-paced food industry, efficiency, consistency, and hygiene are the keys to success. For restaurants, catering units, hotels, and food processing businesses, preparing chapathis manually is time-consuming, labor-intensive, and often inconsistent in quality. Recognizing these challenges, Scanan Engineering, a leading manufacturer of food processing machinery, has introduced the Half Cooked Chapathi Making Unit — an innovative solution designed to streamline chapathi production while ensuring uniform quality and taste.

Why Choose a Half Cooked Chapathi Making Unit?

Traditional chapathi preparation requires skilled labor, precise dough kneading, rolling, and cooking. This process not only consumes significant time but also increases operational costs. With Scanan Engineering’s Half Cooked Chapathi Making Unit, businesses can overcome these limitations.

Key advantages include:

Time-Saving: Automates kneading, rolling, and partial cooking, allowing faster production.

Consistency: Produces uniform chapathis with consistent thickness, size, and texture.

Hygiene & Safety: Built with food-grade stainless steel to ensure safe, contamination-free processing.

Reduced Labor Dependency: Minimizes manual effort, enabling staff to focus on other tasks.

Scalable Production: Ideal for both small and large-scale commercial operations.

By using a half-cooked chapathi unit, businesses can deliver high-quality chapathis with minimal effort, ensuring customer satisfaction every time.

Features of Scanan Engineering’s Half Cooked Chapathi Making Unit

Scanan Engineering’s machines are designed with advanced technology, precision engineering, and user-friendly interfaces. Some of the key features of the Half Cooked Chapathi Making Unit include:

Food-Grade Construction: Made from high-quality stainless steel, ensuring durability, easy cleaning, and compliance with food safety standards.

Automatic Atta Kneader: Efficiently kneads dough to the perfect consistency for uniform chapathi preparation.

Chapathi Ball Cutter: Cuts dough into uniform balls, saving time and ensuring consistency in size.

Half-Cooking Mechanism: Cooks chapathis partially, making them ready for final cooking at a later time, which is ideal for bulk production and storage.

Readymade Chapathi Option: Some models allow full automation for producing ready-to-serve chapathis, enhancing operational efficiency.

Energy Efficiency: Designed to consume minimal power while maintaining high output.

Compact & User-Friendly: Easy to operate with minimal training, suitable for any commercial kitchen setup.

Applications of the Half Cooked Chapathi Making Unit

The half-cooked chapathi machine is versatile and caters to multiple sectors within the food industry:

Hotels & Restaurants: Serve freshly cooked chapathis quickly without compromising taste or quality.

Catering Services: Prepare chapathis in bulk for events, weddings, and corporate functions efficiently.

Food Processing Units: Produce half-cooked chapathis for packaging and distribution.

Institutional Kitchens: Ideal for schools, hospitals, and corporate canteens to manage large-scale meal preparation.

This machine not only reduces labor costs but also enhances the speed and quality of production, making it a valuable investment for commercial food enterprises.

Benefits of Investing in a Half Cooked Chapathi Making Unit

Investing in Scanan Engineering’s Half Cooked Chapathi Unit brings numerous advantages:

Enhanced Productivity: Automates the entire process, allowing businesses to produce hundreds of chapathis per hour.

Consistent Quality: Each chapathi has uniform size, thickness, and texture, ensuring customer satisfaction.

Reduced Operational Costs: Minimizes labor and energy costs while improving efficiency.

Flexibility: Half-cooked chapathis can be stored and finished cooking as needed, providing flexibility in meal preparation.

Hygienic Production: Stainless steel construction and automated processes maintain cleanliness and reduce contamination risks.

These benefits make the unit a reliable choice for businesses looking to scale operations and maintain high-quality food standards.

Why Scanan Engineering?

With years of experience in food processing machinery, Scanan Engineering has earned a reputation for delivering innovative, durable, and efficient machines. Their half-cooked chapathi unit is designed to meet the growing demands of modern food businesses, combining advanced technology with ease of use.

Why choose Scanan Engineering:

Industry-leading expertise in commercial chapathi and bakery machinery.

Robust, long-lasting machines made from high-quality materials.

Excellent after-sales support and technical assistance.

Machines designed for scalability, energy efficiency, and easy maintenance.

By choosing Scanan Engineering, businesses not only get high-quality machinery but also a reliable partner for their food processing needs.

Conclusion

The Half Cooked Chapathi Making Unit by Scanan Engineering is a game-changer for the food industry. It addresses the key challenges of traditional chapathi preparation, including time constraints, labor dependency, and inconsistent quality. By automating kneading, cutting, and partial cooking, this machine ensures speed, efficiency, hygiene, and uniformity — empowering hotels, restaurants, catering units, and food processors to deliver quality chapathis consistently. Contact Scanan Engineering or Visit our Fcatory directly.